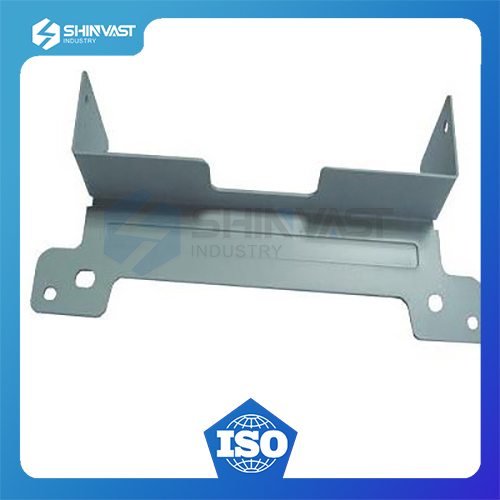

Customized Aluminum Stamped precision Parts

Basic Info

Model No.: SVI-162

Product Description

Not only the whole industry to use it, and everybody comes in contact directly with the stamping products.Like a plane, train, automobile, tractor on many big, in, small stampings.Car body, chassis and circle and other components are stamping processing.According to the investigation statistics, bicycles, sewing machines, watches in 80% of stamping parts;Television, radio, camera is 90% stampings;Shell and food cans, aluminium boiler, enamel POTS bowl and stainless steel tableware, all is to use a die stamping processing products.Even in the computer hardware is lack of stamping parts.

Stamping Operations

Bending - the material is deformed or bent along a straight line.

Flanging - the material is bent along a curved line.

Embossing - the material is stretched into a shallow depression. Used primarily for adding decorative patterns. See also Repoussé and chasing.

Blanking - a piece is cut out of a sheet of the material, usually to make a blank for further processing.

Coining - a pattern is compressed or squeezed into the material. Traditionally used to make coins.

Drawing - the surface area of a blank is stretched into an alternate shape via controlled material flow. See also deep drawing.

Stretching - the surface area of a blank is increased by tension, with no inward movement of the blank edge. Often used to make smooth auto body parts.

Ironing - the material is squeezed and reduced in thickness along a vertical wall. Used for beverage cans and ammunition cartridge cases.

Reducing/Necking - used to gradually reduce the diameter of the open end of a vessel or tube.

Curling - deforming material into a tubular profile. Door hinges are a common example.

Hemming - folding an edge over onto itself to add thickness. The edges of automobile doors are usually hemmed.

Piercing and cutting can also be performed in stamping presses. Progressive stamping is a combination of the above methods done with a set of dies in a row through which a strip of the material passes one step at a time.

Stamping

|

| MAIN PARTICULARS |

| Material | iron, carbon steel, stainless steel, brass, copper, alloy steel, aluminum, cold rolled steel with various plating |

| Standard | ASTM, ASME, DIN, JIS, ISO, BS, API, EN |

| Certificate | ISO9001, BV |

| Processing | Laser/Line cutting, Stamping, CNC Punching, CNC Bending, Welding, Assembling, etc. |

| Finishing surface | Machined surface with tectyl891, anodize, polishing, nickel plating, zinc plating and chrome plating, oxidation, powder coating, painting, etc. |

| Inspection | material, construction, dimension, heat treatment, hardness, NDT |

| Quality | ISO9001, BV, control production |

Our Certificates

- Material certificates EN10204 3.1

- Measuring reports

- Inspection protocol

- NDT reports

- Fixed certificate: ISO9001, BV certificate, CCS certificate

Photos of Aluminum OEM precision stamping parts

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Stamping Parts > Aluminum Stamping Parts